Hale's Dragstrip Dyno shows the difference in performance is 12.18 at 113.60 mph versus 12.13 at 114.00 mph. The dyno estimates the car will run slightly slower at the higher-elevation track despite the identical density altitude, cooler air, and reduced humidity. Then we used his Dragstrip Dyno program to get an idea of how our 3,550-pound street car with 400 hp and an automatic would run at both tracks. We plugged both track conditions into his Weather Station program to get the density-altitude numbers.

Air density free#

On his Web site, Hale has created two very simple programs that are free for anyone to use. This is especially valuable information for bracket racers who strive to make their cars run exactly the same from one run to the next. Many racers are now looking at grains of water per pound of dry air, and if you desire to dig deeply into this, you can read more about it on the Altalabs Web site. That's not much (assuming you can accurately measure a 1/2 degree), but it reinforces the point.

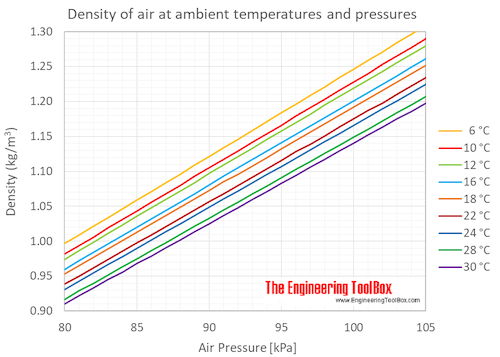

As an example of this, engine builder Jere Stahl recommends trying half a degree of additional timing for every 20 percent increase in humidity. Alternately, humidity levels above 40 percent reduce air density and generally require less fuel and perhaps more timing. Water tends to cool the chamber, but he reports that at levels below 40 percent his engine responds to richer jetting. He says he's seen humidity as low as single-digit percentages in Phoenix, which makes tuning a challenge. Lambeck adds that water in the air has a big effect on the tune-up at both ends of the vapor-pressure scale. Temperature and vapor pressure are the two leading variables that most affect engine performance. These estimates are generalizations based on experience, and it points out that if you become good at keeping records on your car's performance, you will soon be able to predict it rather accurately based on the effect of density altitude. As an example, the new 427ci LS7 Corvette engine rated at 505 hp would probably correct to closer to 530 hp using the performance-industry gross correction factor (C.F. This correction factor reduces the old gross-horsepower output number by roughly 5 percent but is also more realistic. This current Detroit correction factor uses a lower 29.235 inches of Mercury pressure with a higher air temperature of 77 degrees F and zero vapor pressure. In 1972, Detroit switched to a net horsepower correction followed by several more changes, the last of which occurred with SAE standard J1349. Through the early '70s, these were the numbers Detroit advertised and the performance industry followed. As you can imagine, these are ideal or "gross" horsepower numbers that are not practical in the real world but serve as a common reference point. The original "gross" horsepower correction factor includes the standard of 29.92 inches of Mercury (Hg), which is standard sea-level pressure, combined with a temperature of 60 degrees F with no humidity, or zero vapor pressure.

The Shell Game of Correction FactorsSince internal-combustion engines are directly affected by the constant change in atmospheric conditions, long ago the automotive industry came up with a plan for using correction factors to establish a common ground from which all power numbers could be compared.

0 kommentar(er)

0 kommentar(er)